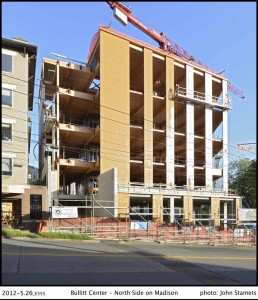

The Curtain Wall System at the Bullitt Center

(C) John Stamets

One of the ways to achieve an Energy Use Intensity (EUI) of only 16 kBtu/ft2 is to design an amazing building envelope. Energy Use Intensity is calculated by taking the total energy the building will use for one year and dividing it by the total enclosed floor space of the building. A typical office building in Seattle has an EUI of about 72 kBtu/ft2. An office building designed to the current Seattle Energy Code would have an EUI of about 51 kBtu/ft2. So it’s easy to see that to meet an EUI of 16, the Bullitt Center needs a high-performance curtain wall. And that is what they are installing right now at the site.

The Living Building Challenge demands that products used in the building can only be sourced from within specific and limited distances, to encourage local manufacturing and eliminate energy-intensive shipping of building products. A curtain wall system engineered by the German company Schuco met the high-performance needs of the design, but the product was only available in Europe. In a remarkable example of creating real change, a partnership was established between Schuco and Goldfinch Brothers, based in Everett, WA. Goldfinch Brothers developed a licensing agreement with Schuco to fabricate, distribute, and install Schuco products in the US. Goldfinch Brothers sent a team to Germany to learn the fabrication process, and now the Schuco-engineered curtain wall systems are fabricated and assembled by Goldfinch Brothers in their Everett facility. These high-performance curtain wall systems are now available for future projects in North America, raising the bar on our domestic manufacturers if they want to compete in this market of super high-performance building components.

Goldfinch Brothers is currently installing the Schuco-engineered curtain wall in the Bullitt Center.

The Schuco curtain wall system is super-insulated. The glass units are triple-pane and measure 2” thick. Each of the larger glass window units weighs 468 pounds. Schuco has engineered a mullion that is carefully designed to eliminate thermal bridging. The glass rests against foam along the aluminum frame extrusion. A pressure cap is screwed on from the exterior once the glass is in place to complete the seal. Around the entire frame a “Schuco flap” adds to the high performance of the envelope. It will be four or five inches wide and goes around all four sides of the window unit and will be caulked and sealed to the Prosoco layer of the wall assembly, creating a strong seal so that cold air cannot infiltrate.

The system is also super-tight. The gaskets at the windows are designed to seal the window tightly to reduce air infiltration. The windows open straight out. Because they open straight out, there is even pressure on the window gasket so it will last longer and maintain a tighter seal than a typical casement or awning window gasket. This extends the life of the gasket and helps maintain a tight seal when the window is closed.

The Schuco curtain wall system at the Bullitt Center is also super-adaptive. It is “switch-rich” and flexible to adapt to changing conditions. The window units will be installed pre-wired and are paired with internal and external shades. The skin is operable; a digital controller will operate the windows, as well as the interior and exterior shades, in order to manage both glare and heat gains. There will be an override button to allow the occupants to open the windows, but only within a certain range of indoor and outdoor temperatures. Once the outside air is too hot or cold the control system will establish the most energy-efficient method for keeping the interior comfortable. For instance, on warm days the windows will open during the night to let in cool air. By 5am the windows will close and the blinds will lower to keep the interior cool as the outside air heats up. The interior and exterior shades of the building act like eye lids and the iris of an eye. They deploy up or down and will open and close to adapt to indoor and outdoor conditions. The external shades will manage the heat of the sun while the internal shades will manage light and glare. Since the windows open straight out they won’t get in the way of either set of shades. Another advantage to the window opening straight out is that it creates a larger effective window opening compared with casement and awning windows. Cooling and providing fresh air can be energy intensive, so passive cooling and ventilation will be important ways to conserve energy.

The sophisticated building envelope designed for the Bullitt Center will result in less energy demand to heat and cool the building. The success of the high-performance envelope, designed through the collaborative efforts of the architects, engineers, and contractors, will allow the building to meet the stringent energy goals set out by the team.